Decolorizing Glass With Manganese

by Rick Baldwin

Reprinted from "Crown Jewels of the Wire", July 1985, page 23

To the insulator collector colored glass has special appeal,

and the challenge of acquiring the wide variety of purple and sun-colored

amethyst (SCA) insulators which are known to exist can be attributed to almost

every major insulator manufacturer. The shades, tints and color variations which

exist are numerous, ranging from the pink, rose and burgundy tints of western

glass to the deep purples which are common to Brookfield, Hemingray, Australian

and Canadian glass. Threadless and other early telegraph insulators have also

been found in amethyst and scarce puce shades.

Colored glass is usually made by

adding an oxide of transition metal to the glass mixture, but the final color

produced will depend upon the interactions between

- the valence or oxidation

state of the metal,

- the compositions of the base glass, and

- the heat

treatment to which the glass is subjected.

The chemistry associated with the

transition element manganese is primarily responsible for the purple and

amethyst colorations found in glass.

Soda-lime glass, which is the common base

composition for bottles and insulators, almost always contains iron oxide as an

impurity, and a small percentage of iron in the glass will give it a green

coloration. Around 1880, a demand for clear glass for food preservation

containers forced manufacturers to perfect techniques of decolorizing

aqua-colored glass. Manganese was commonly employed as a decolorizing agent,

until approximately 1915, at which time World War I cut off the main source

(Germany) of this element. During the period 1915 to 1930, selenium, which

imparts a straw, pink, or "honey" tint to glass, was used as a

decolorizer.

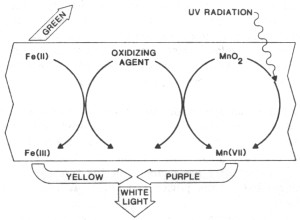

The initial step in decolorizing glass was to add oxidizing agents

(such as potassium nitrate and red lead) to the melt. The iron impurities would

thus be oxidized to the +3 state Fe(III), which imparted a much weaker yellow

color to the glass than the bluish-green color of Fe(II). Adding manganese

dioxide (MnO2) to the melt would aide in oxidizing the iron, and the manganese

would also be oxidized to a chemical state (e.g. MN(VII)) having a

characteristic lavender color which would neutralize the yellow-green color due

to the iron impurities.

Substances exhibit color because they can absorb selected wavelength or

energy ranges from white light and transmit others. Due to its discrete

electronic structure, the highest oxidation state of manganese, Mn(VII), will

absorb electromagnetic radiation in the green region of the visible spectrum.

The energies on either side of this region, which correspond to blue and red

light, will be transmitted (or reflected) and blend to produce the color

sensation of purple or magenta to the human eye. The purple color of the Mn(VII)

ion and the yellow-green color of the iron impurities are complimentary that is,

when mixed in equal proportions, they produce white light or the sensation of no

color at all. During the decolorizing process, if the manganese content of the

glass melt was too high and the purple color was too evident, a reducing agent

(such as a piece of charred wood or a potato) would be added to reduce the

excess manganese back to a lower (colorless) oxidation state.

Deep purple-colored glass would be produced if the concentration of manganese

in the melt was high and if strongly oxidizing conditions were present. It is

conceivable that purple insulators were purposely produced for their beauty or

for identifying or distinguishing different lines. The final color obtained with

manganese present in the glass mixture (pinkish-purple to violet) would depend

on such factors as

- whether lead or barium was a constituent in the glass

mixture base,

- the presence of soda or potash as the alkaline constituent,

- the reducing or oxidizing conditions of the furnace, and

- the heat and

duration of the "found."

Nickel oxide could also be used as an

additive to impart stable purple shades to glass, depending upon the composition

of the base glass: a brownish-violet color would result with soda-lime glass, a

redish-violet color with potash-lime glass, and a deep purple color with lead

silicate glass.

"Black glass" is usually made by adding MnO2 to the melt, either

alone or along with oxides of nickel and chromium. A beautiful puce color is

obtained when purple and amber coloring agents are blended together. Sun-colored

amethyst glass results from the exposure of manganese-containing decolorized

glass to the ultraviolet (UV) rays of the sun. Any manganese still present in

the reduced chemical state will absorb UV-radiation, which is sufficient in

energy to oxidize it to the purple-colored chemical state. The extent of purple

coloration in the glass is due to the length of exposure to the UV-radiation.

Glass cannot be effectively sun-colored through a glass window because the

window glass will absorb much of the sun's ultraviolet rays.

It is possible to artificially

sun-color glass by exposing the glass to an intense UV-light source or to other

sources of ionizing radiation. A Germicidal Lamp in a "purpling box"

is often employed to accelerate the sun-coloring process.

In conclusion, every

collector knows that the color which the eye perceives an object to have may

differ when the object is viewed under different lighting conditions. Natural

sunlight produces a fairly uniform distribution of visible light. However, light

from other sources have different spectral energy distributions -- e.g.,

incandescent illumination contains more red light than green light. The actual

color that is perceived is a "blend" at each wavelength of

- the

spectral reflectance or transmission of the object,

- the spectral sensitivity

of the eye, and

- the spectral energy distribution of the light source.

If any

one of these contributing factors is changed, then the color of the object may

appear different.

|